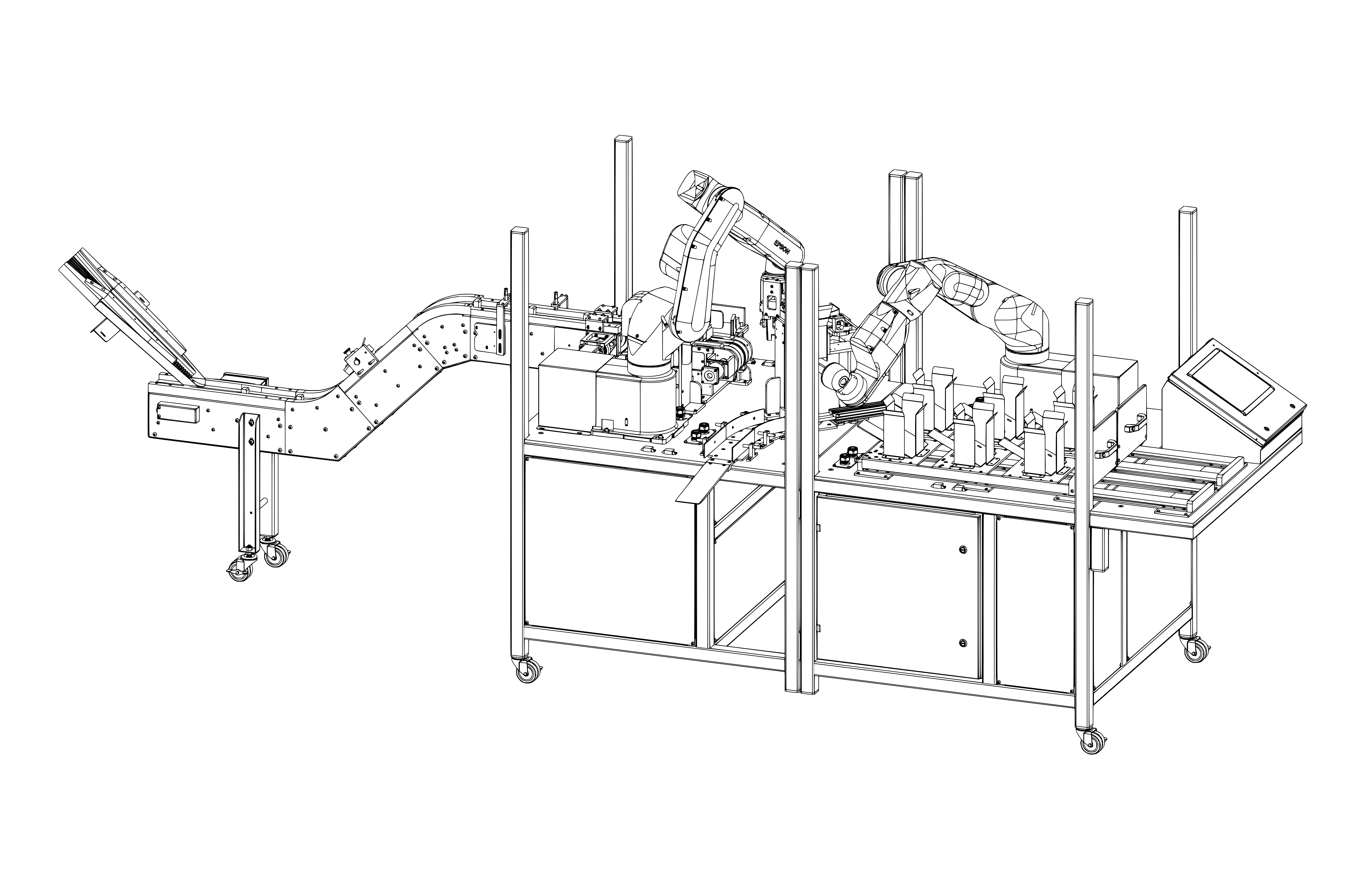

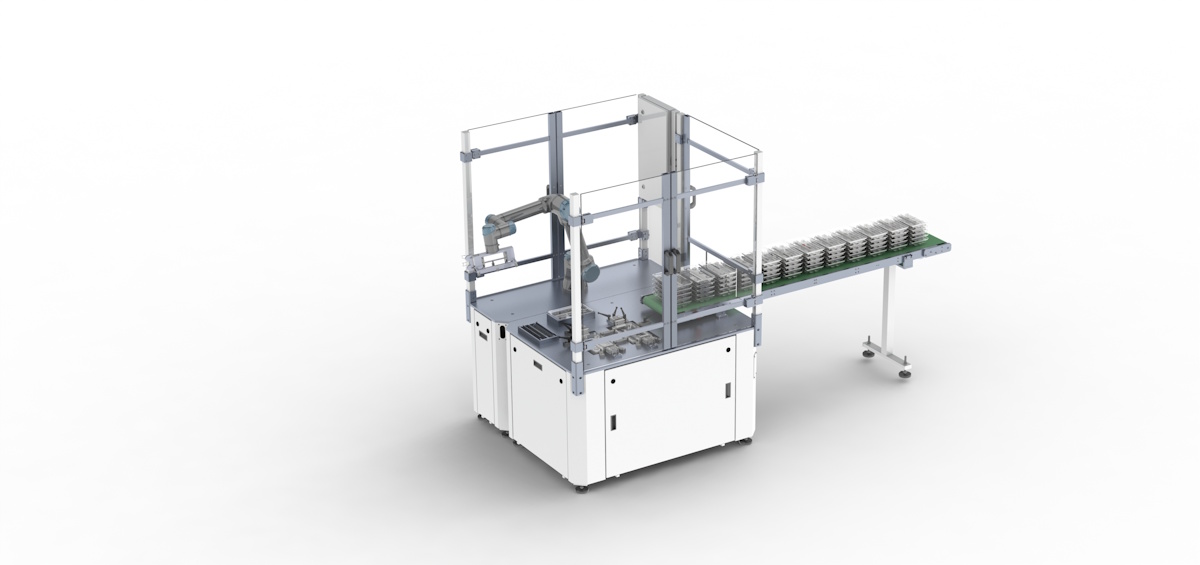

Automated Packaging for Formed Wire Components

Challenge:

A client in the metal fabrication industry needed to automate the packaging of small, complex wire components coming directly from a CNC forming machine. The process involved picking individual parts, neatly stacking them, placing them into a container, and securing the lid.

Issues:

Labor: The tedious, manual process required a dedicated operator, representing a significant labor cost.

Quality & Consistency: Manual handling resulted in inconsistent packaging, affecting product presentation and quality.

Throughput: The manual packaging process was a bottleneck, unable to keep pace with the CNC machine's output, limiting unattended operation.

Solution:

HQA engineered a complete, turnkey packaging cell using our modular machine platform and a collaborative robot. The system autonomously takes parts from the CNC outfeed, neatly packages them, and transfers the finished containers to a conveyor. Our engineers also designed a new, custom packaging container for the client to improve product handling and presentation.

HQA engineered a complete, turnkey packaging cell using our modular machine platform and a collaborative robot. The system autonomously takes parts from the CNC outfeed, neatly packages them, and transfers the finished containers to a conveyor. Our engineers also designed a new, custom packaging container for the client to improve product handling and presentation.

Results:

Autonomous Operation: The system allows for four hours of completely unattended machine operation.

Labor Requirement: The dedicated material handler was eliminated and re-tasked to a higher-value role.

Product Quality: The new container and automated process ensure perfectly packaged, presentation-ready products every time.

ROI: 16 Months.