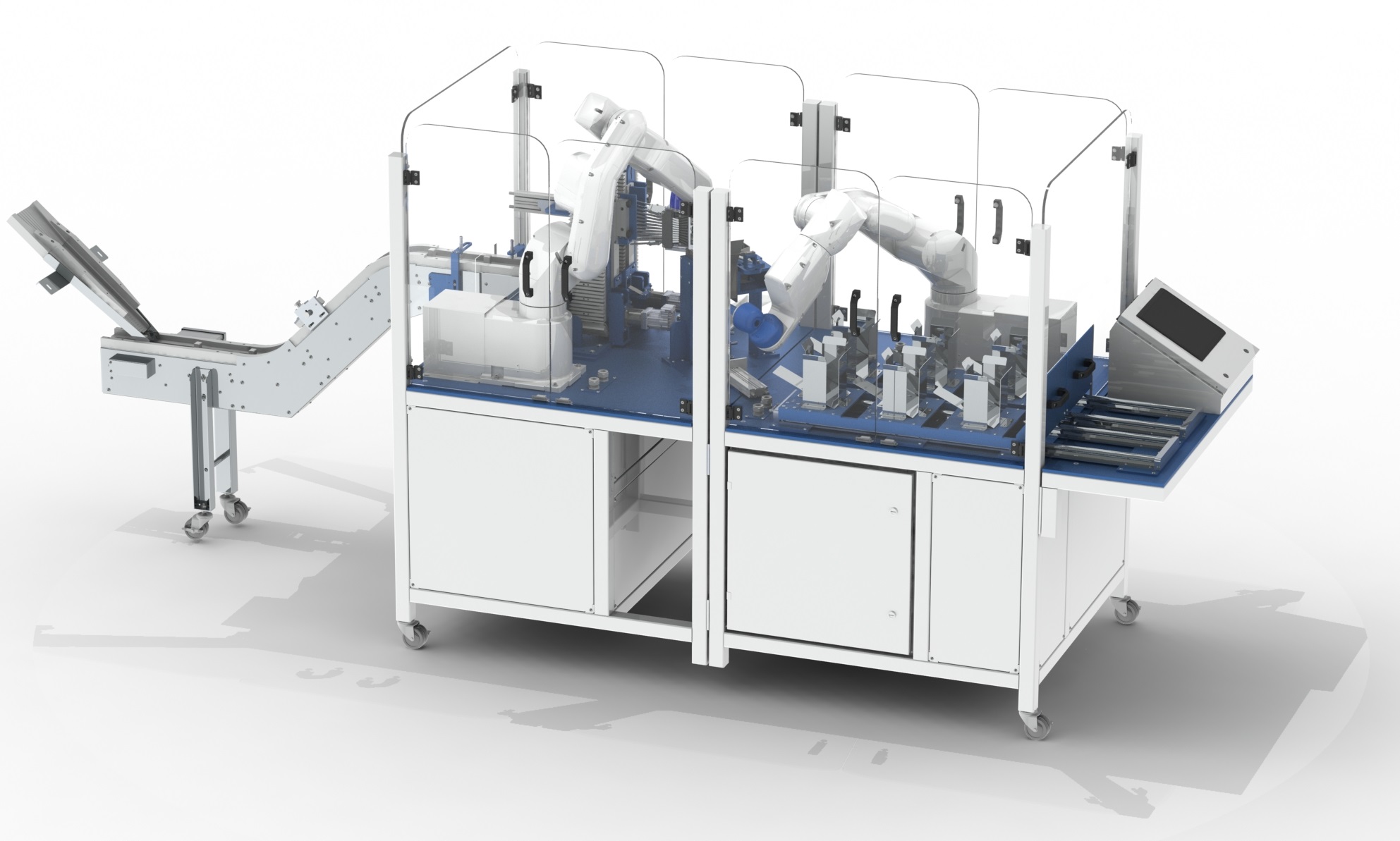

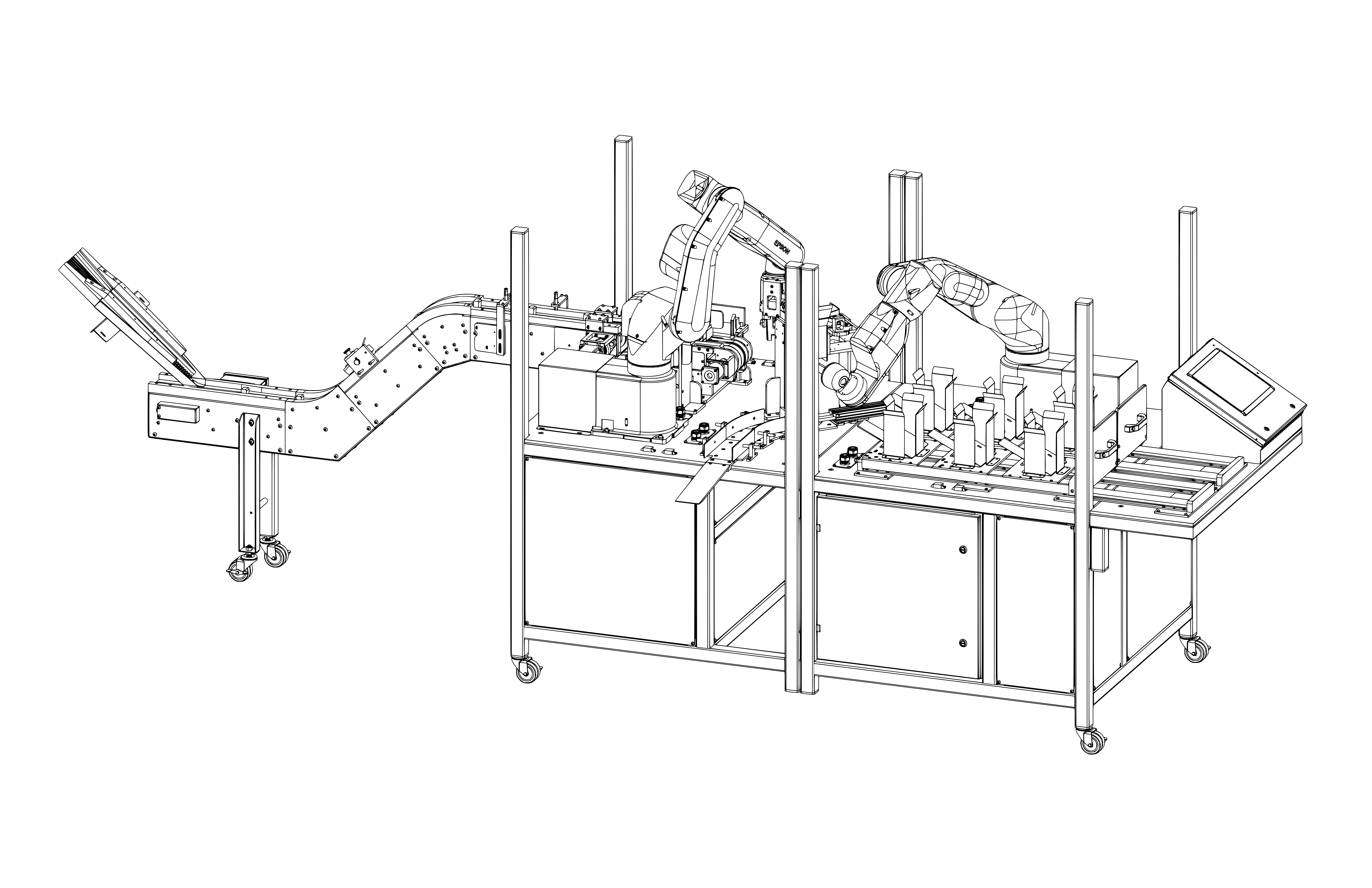

Automated Pouch Casing System

Challenge:

A client in the packaging industry was manually forming cases, grouping products, and loading them. This multi-step process was slow, labor-intensive, and created a bottleneck in their production line.

Issue:

Labor: Required three full-time material handlers, making it difficult to staff and leading to high labor costs. Throughput: The manual pace could not keep up with production demands, limiting overall plant output. Flexibility: The existing process was rigid and could not be easily adapted for future product variations.

Solution:

HQA partnered with the client to design, manufacture, and integrate a complete, automation solution. We developed a flexible, robot-centric system to manage the entire workflow. The solution was built on HQA's modular platform, featuring a welded steel frame, integrated safety systems, and a centralized Allen-Bradley control panel. The entire system was built in-house at our Illinois facility. To meet the unique demands of this application, HQA designed and manufactured several key subsystems.

Result:

Production Rate: 85 pouches per minute.

Production Consistency: Fully automated process eliminated human variability and ensured consistent output.

Labor Requirement: Reduced from 3 full-time operators to 1 part-time operator.

ROI: 12 Months.