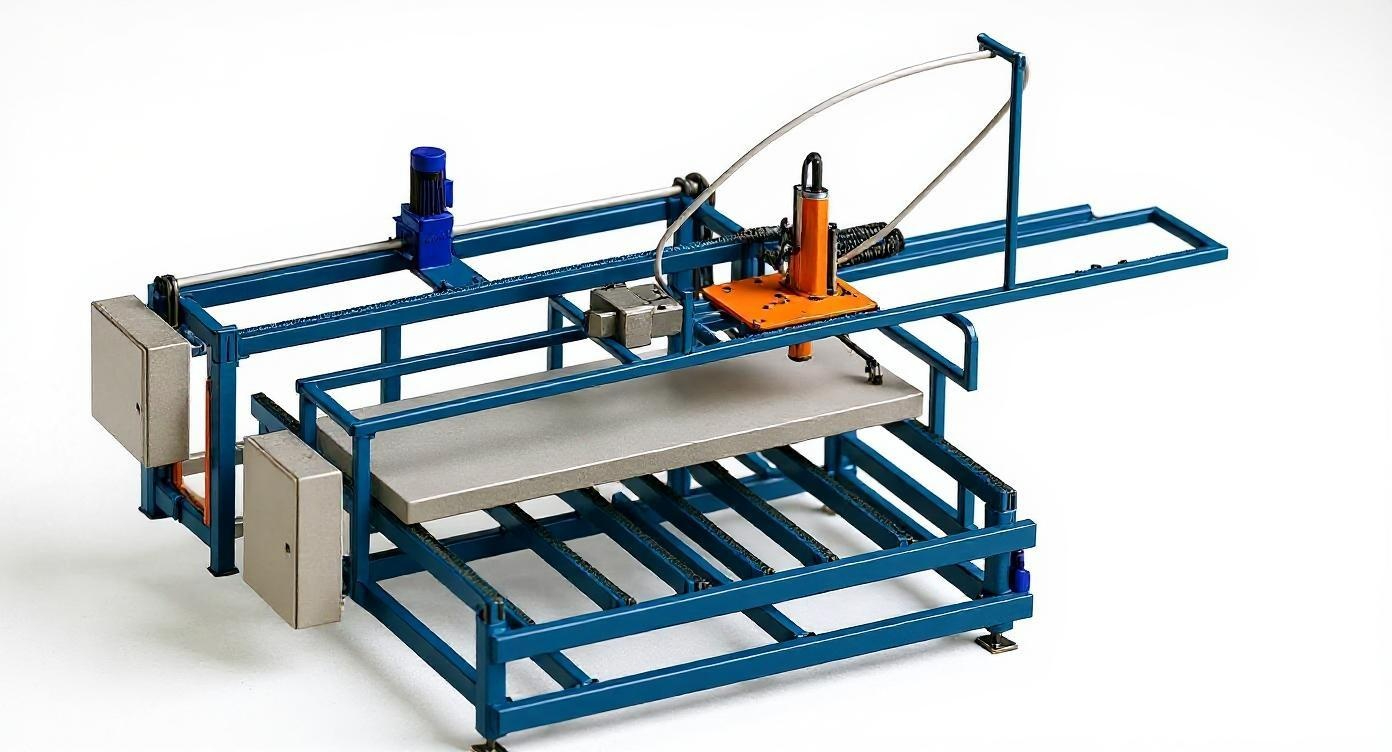

Automated Sheet Destacker & Lamination Infeed

Challenge:

A client needed to fully automate the process of loading large, heavy sheets into a lamination line. The manual process of handling full pallets of up to 150 sheets was slow, physically demanding, and created a major bottleneck for their entire production line.

Issues:

Ergonomics & Safety: Manually lifting and loading large sheets posed a significant risk of operator injury.

Machine Downtime: The high-value lamination line was frequently idle while operators struggled to manually load the sheet

Solution:

In partnership with a T&T and Dynamech Design, HQA manufactured and integrated a heavy-duty robust, fully automated sheet destacking and feeding system. The machine accepts a full pallet of 150 sheets. A gantry system equipped with a large-format vacuum gripper picks sheets one by one, verifies that only a single sheet has been lifted, and feeds it into the lamination line. Once the stack is depleted, the machine automatically ejects the empty pallet from the bottom, allowing an operator to quickly load the next full pallet.

Result:

Improved Safety: The system completely eliminated the manual handling of heavy sheets, removing all ergonomic risks.

Maximized Line Uptime: By consistently feeding the laminator at 5 sheets per minute, the system eliminated the previous bottleneck and maximized production.

Enhanced Process Reliability: The integrated double-sheet detection prevents costly jams, reduces material waste, and protects the downstream equipment.