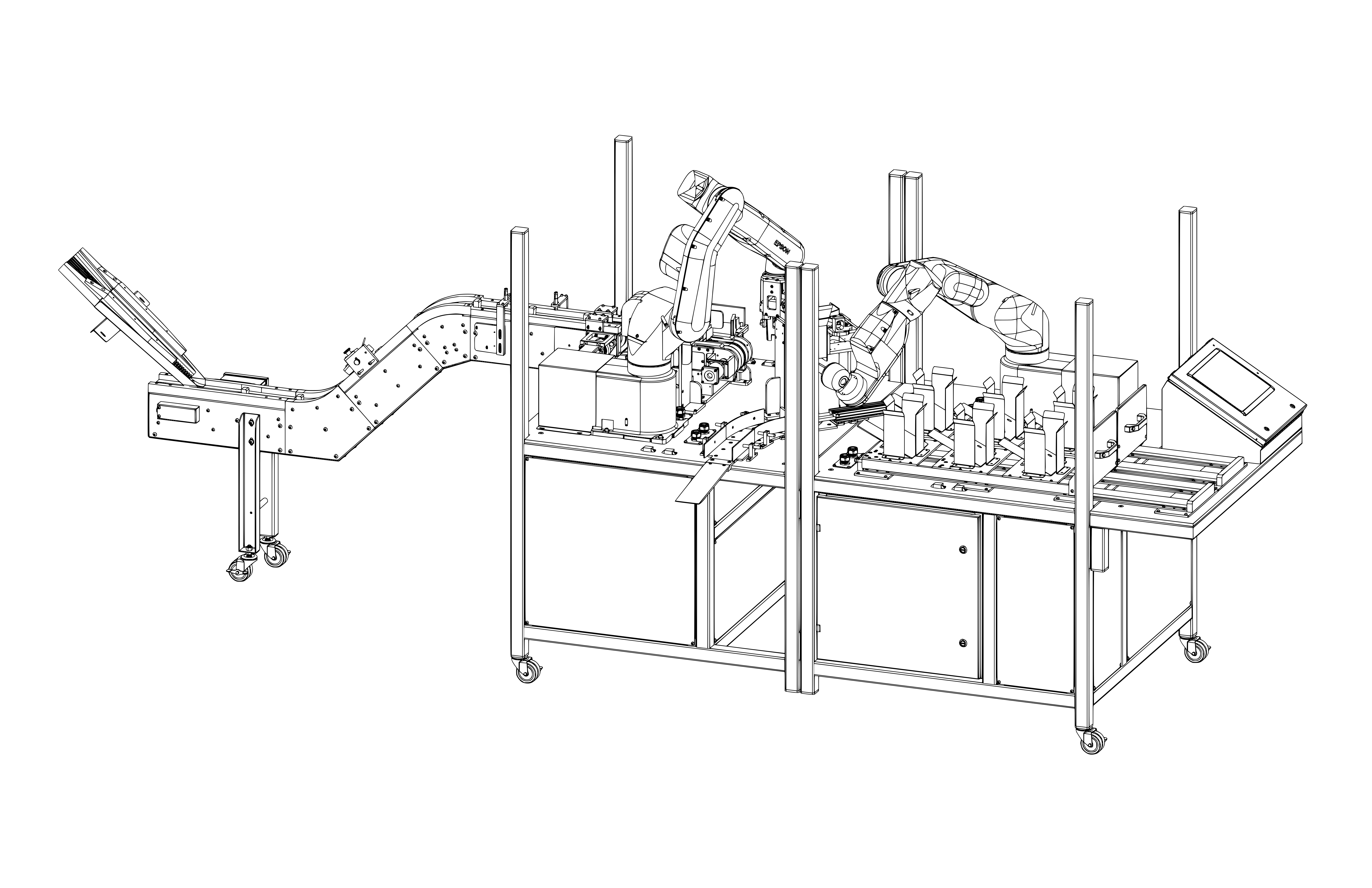

Automated Wet Cast Demolding & Finishing Line

Challenge:

A client in the building materials industry needed a comprehensive, automated solution for their post-curing process. Their workflow required several distinct steps—demolding the cured stone, painting the product, and stacking the finished goods onto pallets—which, if done separately, would be inefficient and labor-intensive.

Issues:

Process Bottlenecks: A disconnected workflow with manual handling between demolding, painting, and stacking would create significant delays and limit overall production capacity.

Labor Intensity: The process would require multiple operators to move heavy products between stations, leading to high labor costs and ergonomic risks.

Solution:

In partnership with Dynamech Design Inc., HQA manufactured and integrated a complete, end-to-end demolding and finishing line. The system automates the entire post-curing workflow. Molds are automatically destacked and fed into a demolding station. The finished stones are then transported through an automated painting station before being conveyed to a final station that stacks the painted products onto a pallet, ready for shipping.

Results:

End-to-End Automation: The system combines three distinct processes into one continuous, automated line, drastically improving efficiency.

Reduced Labor Requirements: The integrated line minimizes the need for manual material handling between processes.

Improved Product Consistency: Automating the painting and stacking process ensures a uniform finish and reduces the risk of handling damage.