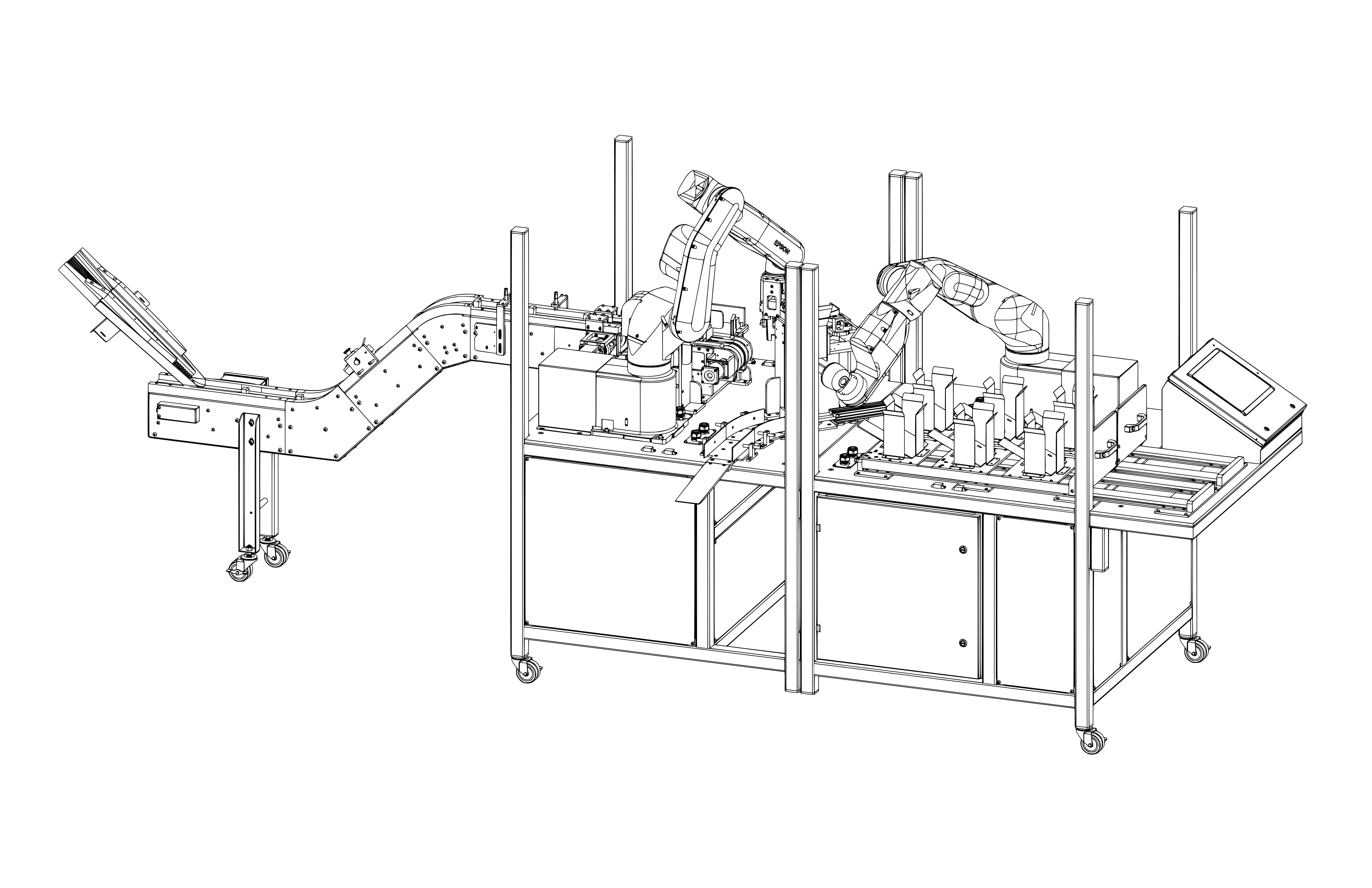

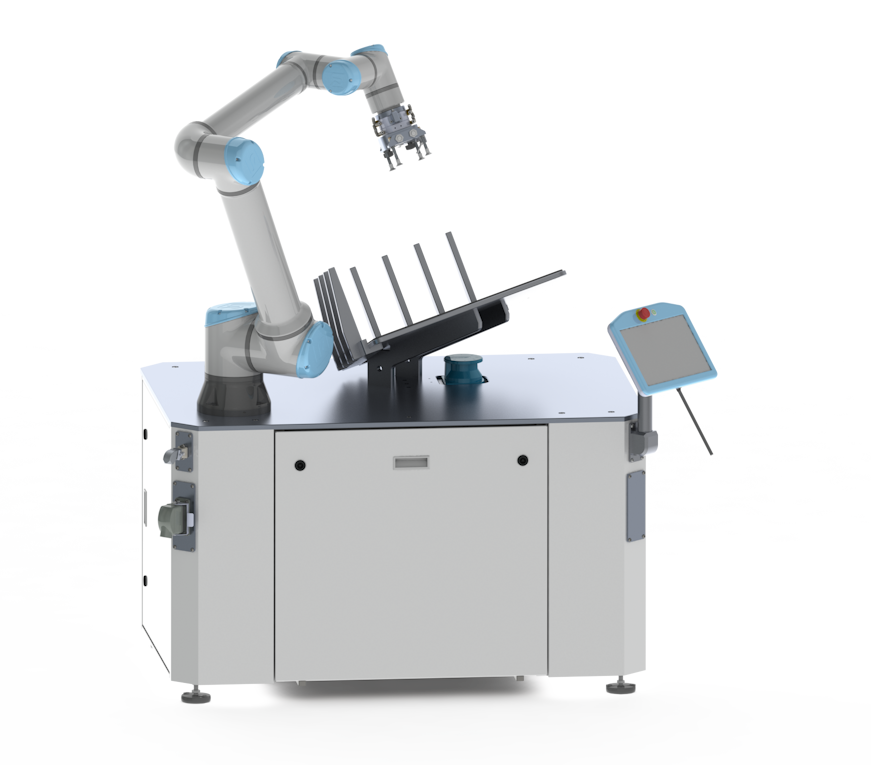

Collaborative Robot CNC Tending Cell

Challenge:

A client in the plastic fabrication industry needed to increase the productivity of their CNC machining operations. A machine operator was dedicated to the repetitive task of manually loading raw material into the CNC and unloading finished parts, leading to significant machine downtime during changeovers and breaks.

Issue:

Machine Utilization: The CNC machine, the most valuable asset in the process, was sitting idle while waiting for the operator.

Labor Allocation: A skilled operator was tied to a low-value, repetitive task instead of performing more critical duties.

Throughput: Production was limited by the operator's pace and could not run unattended after hours to increase capacity.

Solution:

HQA designed and integrated a flexible, mobile CNC tending system built around a collaborative robot. The cell is positioned at the CNC machine, where the robot autonomously picks raw material from a stacked pallet, places it precisely into the CNC fixture, and signals the machine to begin its cycle. After machining, the robot removes the finished part, cleans it with an air nozzle, and places it in a cart for finished goods.

Results:

Unattended Operation: The system allows the CNC to run for hours without an operator, including "lights-out" shifts

Increased Throughput: Without manual loading and changeover, output of CNC is maximized

Labor Optimization:The operator was freed from manual tending and could now manage multiple machines

ROI: 16 Months.