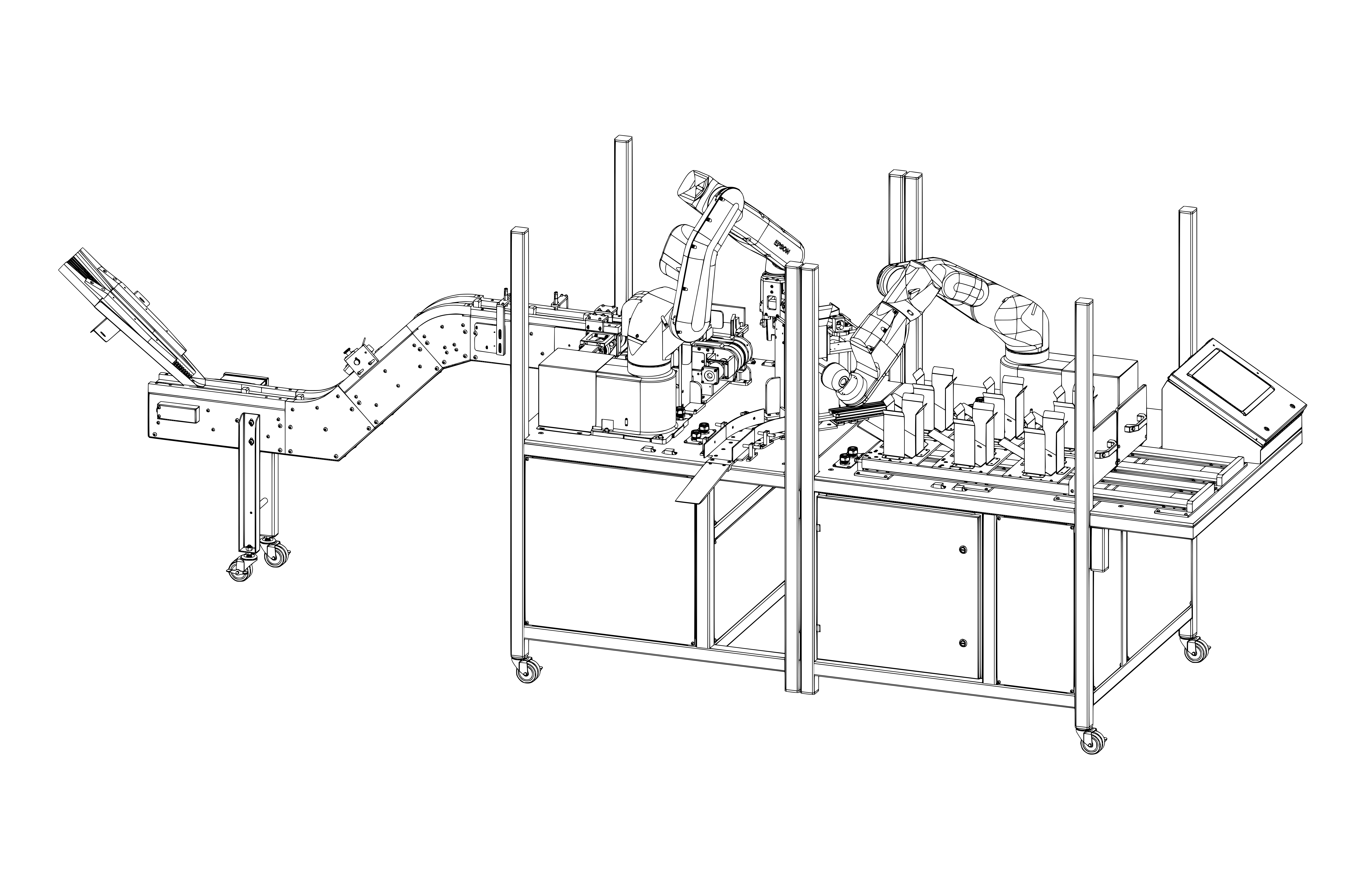

Complete Wet Cast Stone Production Lines

Challenge:

A client in the building materials industry, needed to establish a new, high-volume production facility for wet cast stone. The project required the complete manufacturing and integration of two entire production lines—one for filling molds and another for demolding the finished product—encompassing approximately 20 individual machines.

Issues:

Scale & Complexity: The project involved creating a complete, end-to-end manufacturing process from the ground up, requiring seamless integration between dozens of machines.

High-Volume Throughput: The lines needed to support a high-volume production environment, which was impossible to achieve with manual or disconnected processes.

Solutions:

In partnership with the Dynamech Design Inc., HQA provided the complete manufacturing and integration for two massive production lines. The first line automates the wet cast filling process, while the second, separate line manages the demolding of the cured stone products. The entire system is a network of nearly 20 interconnected machines that fully automates the material handling and production flow from start to finish.

Results:

Enabled High-Volume Production: The two lines provide the client with a complete, high-capacity manufacturing facility.

End-to-End Automation: The system drastically reduces the need for manual labor and material handling across the entire production process.

Consistent Product Quality: By automating the filling and demolding processes, the system ensures every product meets the same high-quality standard.