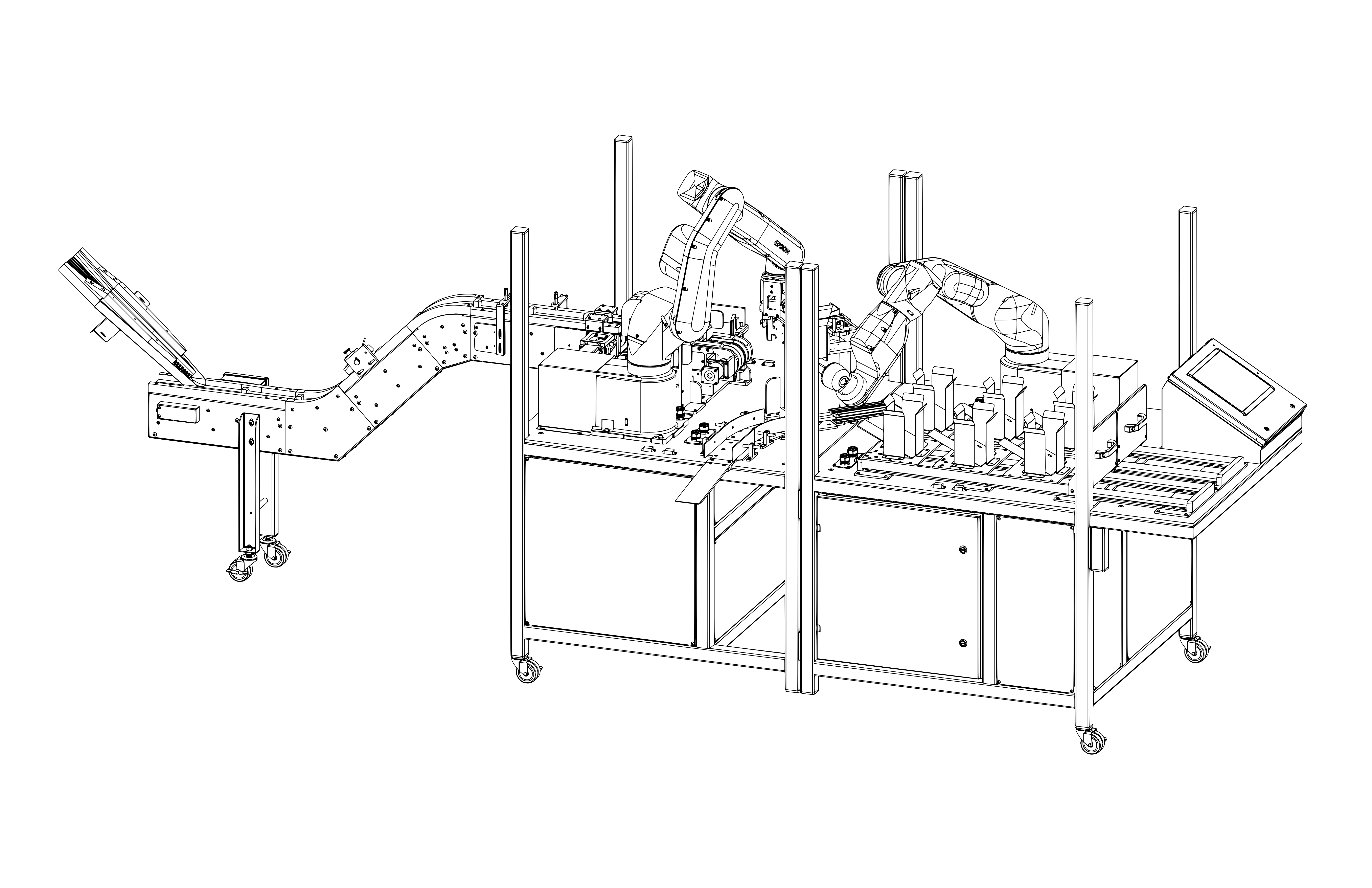

EGR Cooler Bracket Installation Machine

Challenge:

A client in the automotive industry, needed a robust system for a critical assembly task: installing a bracket onto a cooler assembly. The process involved precise alignment, securing straps, and applying an exact amount of torque to shear nuts, all while recording the data for full traceability.

Issues:

Traceability: System to log the final torque value for every part, a critical requirement for automotive components.

Quality & Consistency: Manually torquing shear nuts created a high risk of under-torqued or over-torqued fasteners, leading to potential part failure.

Solution:

HQA designed and built a semi-automated workstation that guides an operator through the complex assembly process while automating the critical torquing and data-logging steps. The station features a large, motor-driven rotary fixture that holds the main assembly. After the operator loads the parts and hand-starts the nuts, they use an integrated DC electric torque gun to secure the fasteners. The system verifies and records the final torque for each nut, ensuring a perfect, fully traceable assembly every time.

Results:

100% Torque Traceability: The system logs the final torque data for every fastener on every part, providing a complete quality record.

Guaranteed Assembly Quality: The DC electric tool and guided process eliminate the risk of incorrect torque, ensuring every part meets specification.

Optimized Ergonomics & Workflow: The large rotary fixture minimizes operator movement and simplifies assembly task.