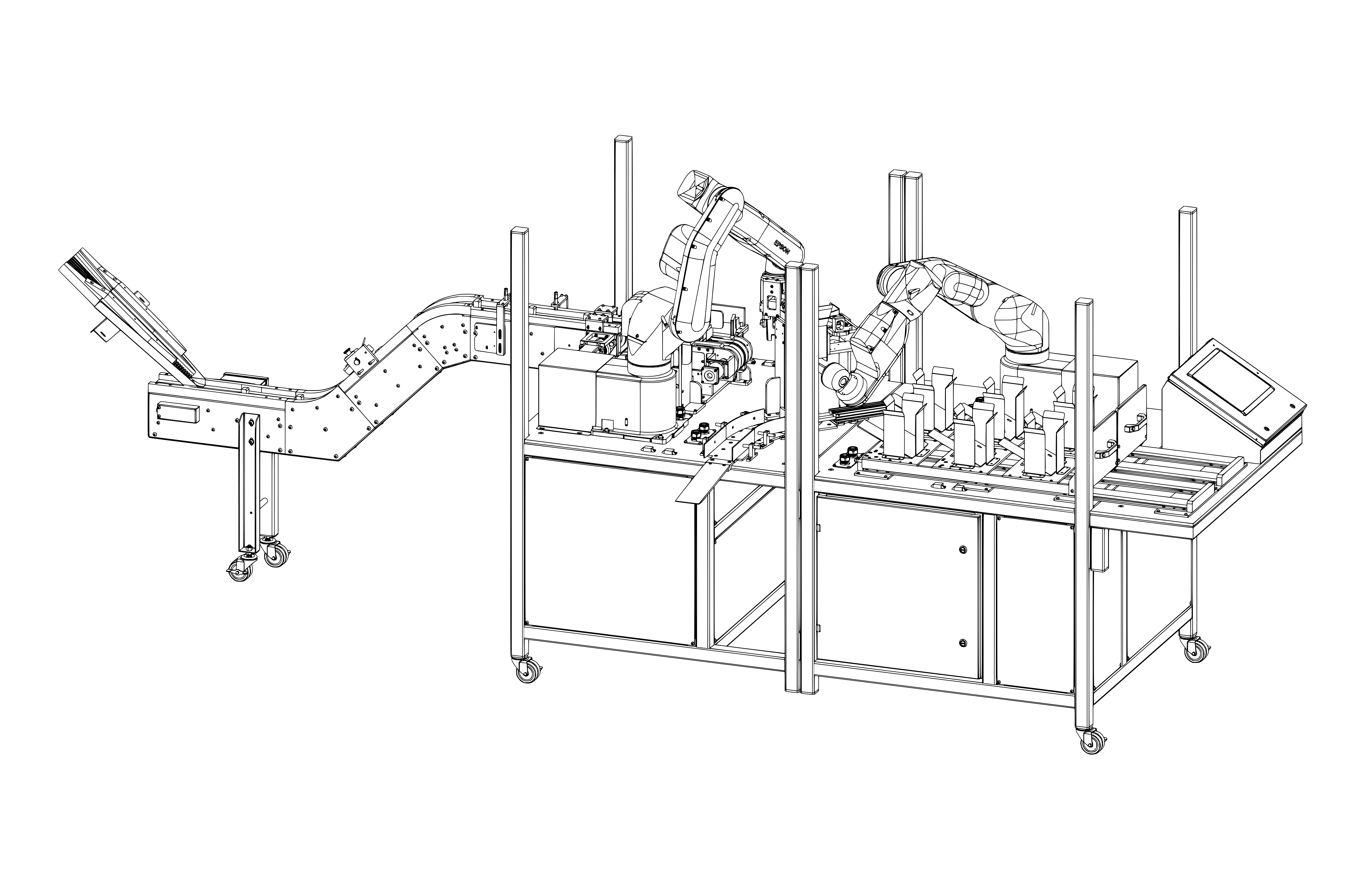

Error-Proofing & Assembly Stations for Automotive Components

Challenge:

A client, needed to automate assembly processes for their fluid conveyance products. The tasks—one for heat sleeve crimping and another for filter installation—involved multiple steps and required 100% quality verification to meet automotive standards.

Issues:

Quality Risk: Manual assembly prone to errors, which could lead to part failure in the field.

Process Control: The assembly processes required a high degree of precision and repeatability.

Traceability: There was no automated system to verify and log that every assembly step was completed correctly for every part.

Solution:

HQA partnered with Senior Flexonics to design and build two distinct, semi-automated stations, each tailored to a specific product line. These operator-loaded machines guide the user through the process and then automate the critical assembly and inspection tasks. This approach ensures that every step is performed and verified correctly, guaranteeing a defect-free part every time.

Results:

100% Error-Proofing: Automated checks completely eliminate the risk of assembly errors on both product lines.

Process Consistency: The stations deliver a repeatable, controlled process, ensuring every part meets exact specifications.

Cycle Time: Both stations were designed to meet the production target with a consistent cycle time of 15 seconds per part.

ROI: 12 Months.