Heavy-Duty Wet Cast Stone Production Line

Challenge:

A client in the architectural materials industry needed to automate their production of large-format wet cast stone. The size and weight of their molds made manual handling impossible and required a robust, industrial-scale automation solution for their filling and demolding processes.

Issues:

Extreme Physical Demands: The weight of the large molds made manual lifting a significant safety risk and was not a feasible option for a production environment.

Production Inefficiency: The slow, careful process required to move the heavy molds created a major bottleneck, limiting the client's ability to meet volume targets.

Solution:

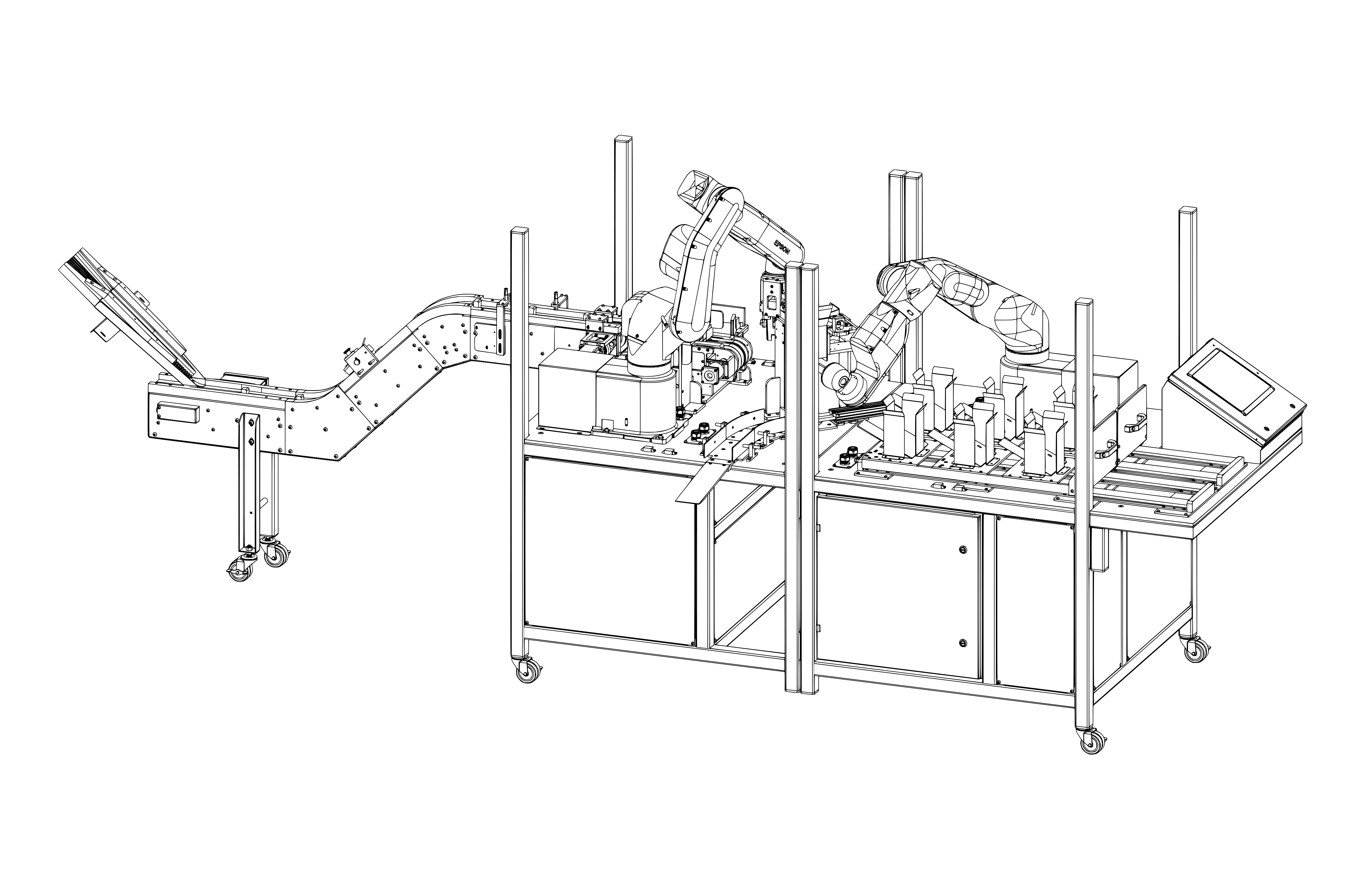

In partnership with Dynamech Design Inc., HQA manufactured and integrated a complete, heavy-duty production line specifically engineered to handle large-format molds. The system automates the entire process, including the filling of the molds with wet cast stone and the subsequent demolding of the cured products. The line is comprised of multiple interconnected machines designed for industrial durability and the unique challenges of large-scale cast stone production.

Results:

Enabled Large-Format Production: The heavy-duty system provides the client with the capability to safely and efficiently produce large-scale architectural stone.

Eliminated Manual Handling: The end-to-end automation completely removes the need for operators to manually lift or handle the heavy molds and products.