Lamination Sheet Cooling & Drying Tunnel

Challenge:

Challenge: Following a high-temperature lamination process, a client needed an effective way to rapidly cool and dry large sheets. Without a dedicated cooling solution, the hot, wet sheets could not be handled or stacked, creating a major process bottleneck and risking product damage.

Issues:

Product Quality: Hot sheets coming directly off the line were prone to warping, surface blemishes, and sticking together if stacked too soon.

Safety & Handling: Attempting to manually handle hot, wet sheets was inefficient and posed a safety risk to operators.

Solution:

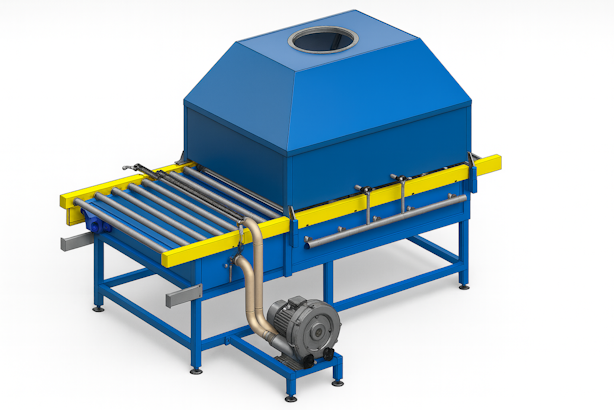

In partnership with a T&T and Dynamech Design, HQA manufactured and integrated a cooling tunnel that seamlessly integrates into the client's lamination line. As hot sheets exit the laminator, they are immediately transported through the tunnel on a roller conveyor. Inside, high-volume blowers and targeted air knives rapidly and evenly cool the sheet's surface while simultaneously drying it, ensuring the product is cool, dry, and stable when it reaches the end of the line.load the next full pallet.

Results:

Improved Product Quality: The controlled cooling process eliminates heat-related defects such as warping, ensuring a flat, high-quality final product.

Increased Throughput: The cooling tunnel allows the main lamination line to run at its maximum speed.

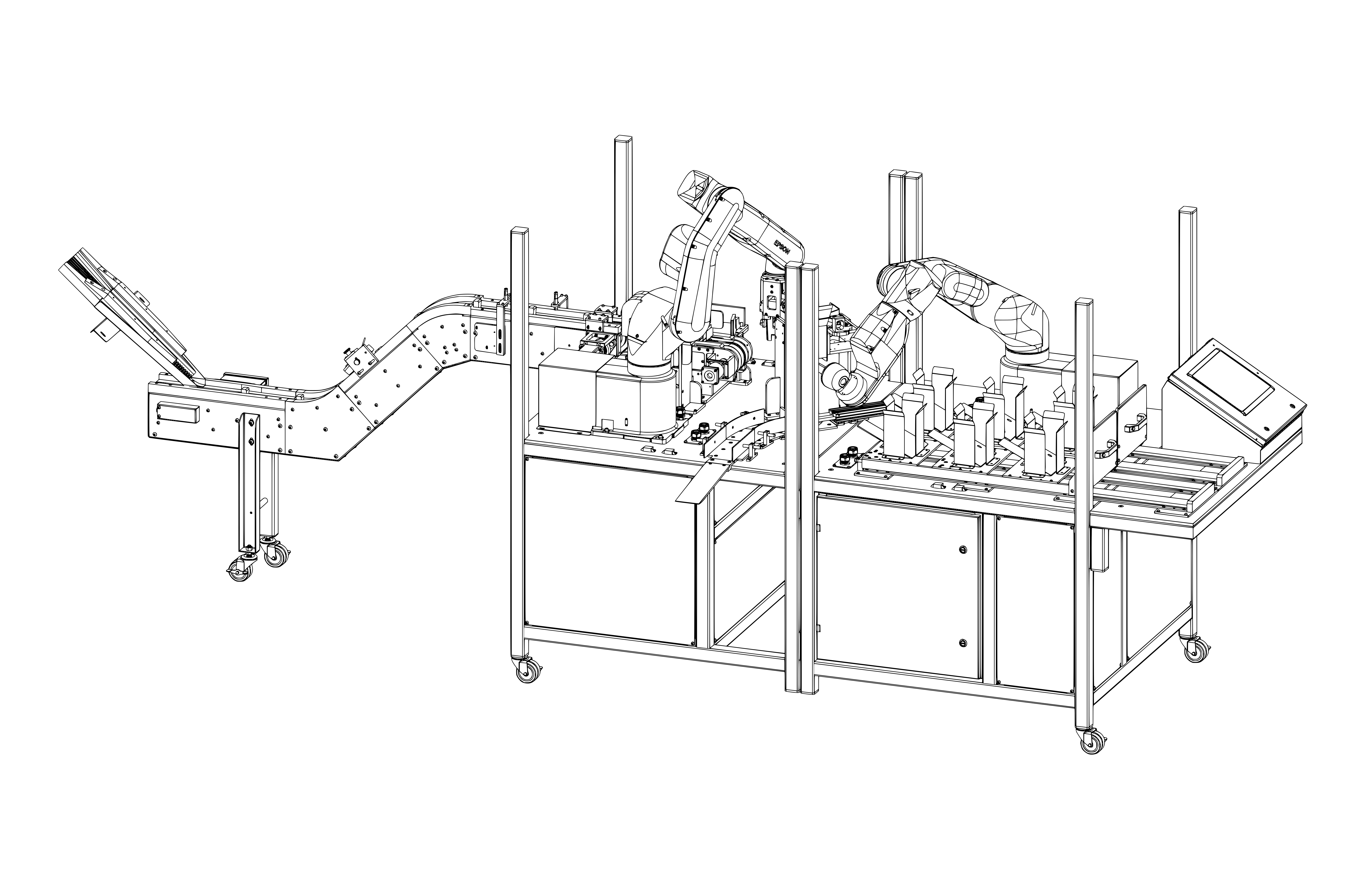

Enabled Automation: By delivering a cool, dry, and stable product, the system enables automated stacking and handling at the end of the line.