Quick-Change PVC Laminator

Challenge:

A client in the building materials industry, FlashCo, needed to improve the efficiency of their new lamination line. Their existing process for laminating PVC coating to sheet steel was plagued by extended downtime during roll changes, a common problem in continuous web processes.

Issues:

Downtime: Changing over the large, heavy rolls of PVC material was a slow, manual process, stopping the entire line.

Throughput: The frequent and lengthy changeovers created a major bottleneck that limited the total output of the line.

Process Inefficiency: Operators were spending too much time on changeover tasks instead of overseeing production and quality.

Solution:

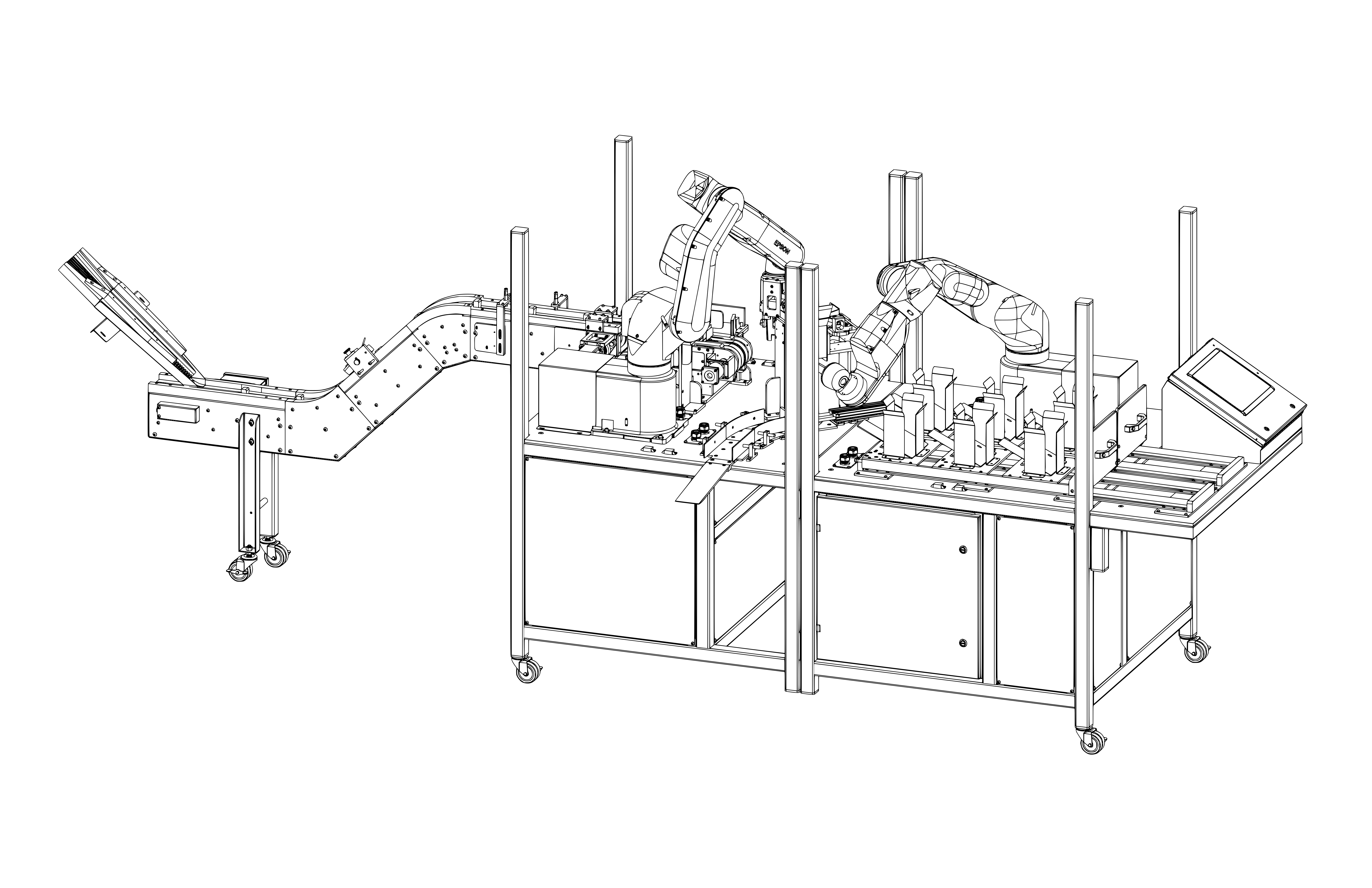

In partnership with a T&T and Dynamech Design, HQA manufactured and integrated a heavy-duty PVC laminating machine with a dual-lift system specifically designed for rapid changeovers. While one roll of PVC is in production, an operator can safely load and prep the next roll on the second side. When a changeover is needed, the system automatically and quickly switches from the empty roll to the new one, drastically reducing the time the line is stopped.

Result:

Minimized Changeover Downtime: System reduced the time-consuming process of a roll change to just a few minutes.

Maximized Production Uptime: By nearly eliminating changeover downtime, the machine allows for near-continuous production, significantly boosting throughput.