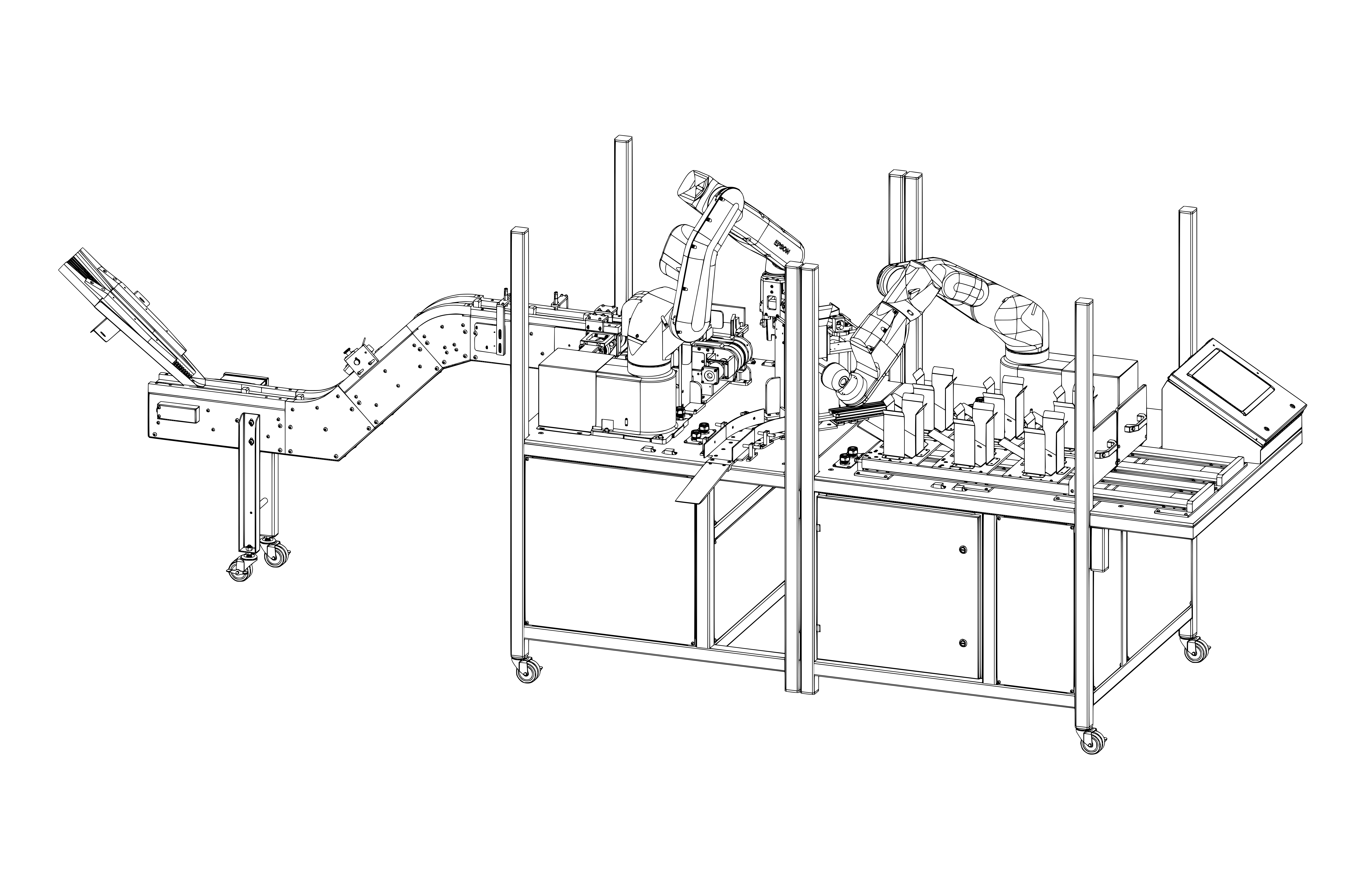

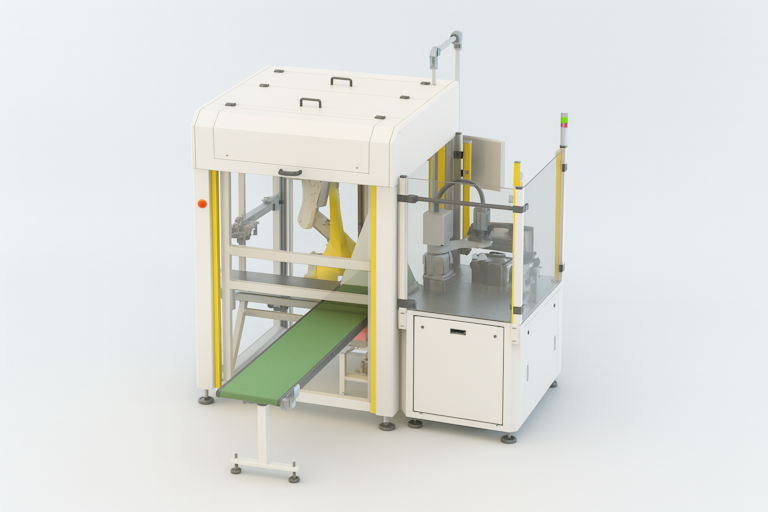

Robotic Assembly & Multi-Point Vision Inspection Cell

Challenge:

A client in the precision manufacturing industry, needed to automate a critical assembly and quality control process. The task required pressing a metal insert into a part and then performing a complex, 100% inspection, esuring zero defects.

Issues:

Quality Control: A manual inspection process was susceptible to human error, creating a risk of non-conforming parts.

Labor: The multi-step process required a dedicated operator for the repetitive tasks, and inspecting each part.

Process Reliability: The manual workflow lacked the repeatability and data tracking needed for modern quality assurance.unattended operation.

Solution:

HQA designed and built a complete, turnkey robotic cell that automates the entire assembly and inspection sequence. An operator loads the part and insert onto a fixture, and the machine takes over. The system features a servo-driven shuttle, a pressing station, and a 6-axis robot that presents the part to multiple high-resolution cameras for a comprehensive quality check before sorting it into "pass" or "fail" locations.

Result:

Quality Assurance: The system provides 100% automated inspection, eliminating human error and ensuring zero defects.

Increased Throughput: The process was automated to a consistent cycle time of 10 parts per minute.

Labor Optimization: The need for a dedicated operator was eliminated, freeing up skilled labor for higher-value tasks.

ROI: 10 Months.